MMB

CAS No. 56539-66-3MMB (3-methoxy-3-methyl-1-butanol) is a unique alcohol solvent produced by Kuraray. It is a clear, colorless, water-soluble liquid with a mild odor. It is recognized as a human and environment-friendly solvent, passed the US EPA's DfE screen for solvents, and is listed on Cleangredients due to its low toxicity profile.

Features

■ Cleaner

Improvement of detergency

MMB improves cleaning power with small amount.

Effect on plastics

MMB does less damage to plastics compare to glycol ethers.

Improvement of stability

MMB reduces viscosity and stabilizes conc. formulations.

Stability under alkaline and acidic condition

MMB is stable at high and low pH.

Evaporation profile

The evaporation rate can be controlled with MMB.

■ Air freshener

Odor

Low in odor

Compatibility with aroma chemicals

High in compatibility with various aroma chemicals

Evaporation profile

Evaporation speed can be controlled, and less variation in composition.

Co-surfactant effect

Less surfactant for water based formulations

Improvement of detergency

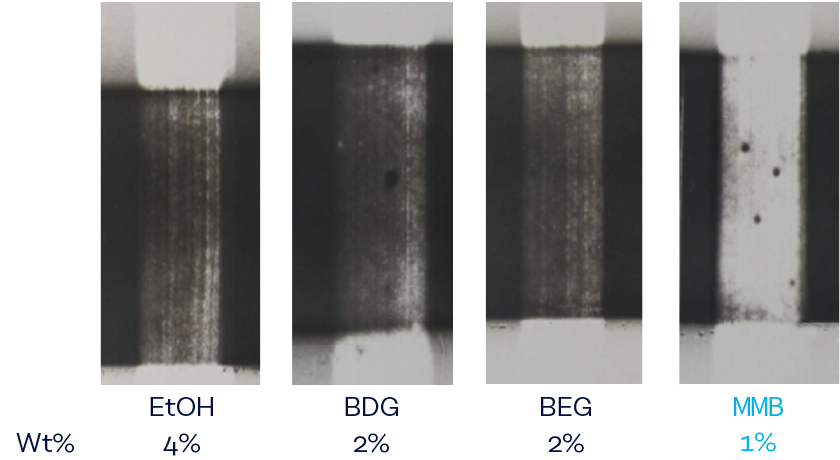

MMB formulation shows the best cleaning performance with lowest quantity.

Test 1

The detergency of a stain with four different detergent formulations was checked.

-

-

- Stain

- Peanut oil, Kaolin, Carbon black

- Test formulation of cleaner

- Surfactants, solvents, water, and others

- EtOH

- Ethanol

- BDG

- Diethylene glycol mono-butyl ether

- BEG

- Ethylene glycol mono-butyl ether

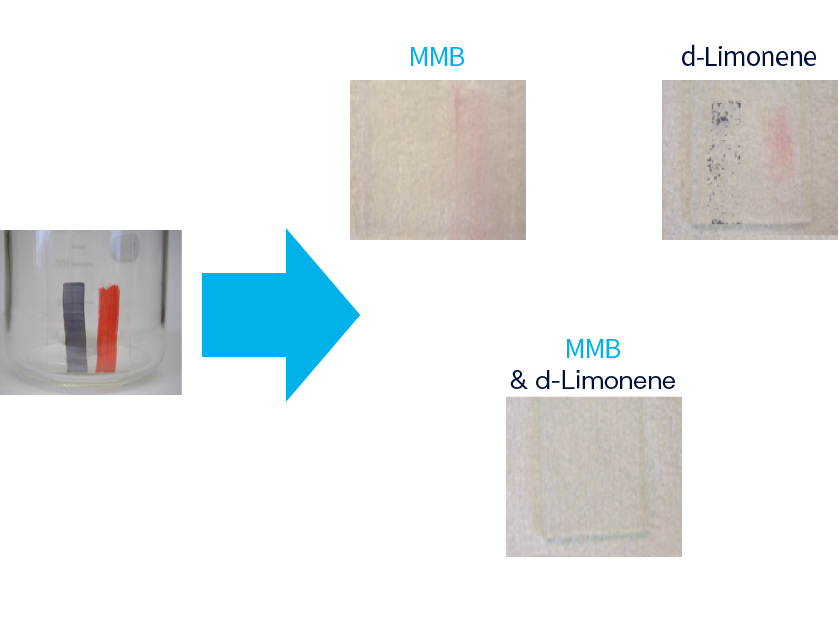

MMB has synergy in detergency with hydrocarbons such as d-Limonene.

Test 2

The detergency of the marker line on glass with solvents was checked.

- Test method

- Glass plates with lines drawn with a permanent marker (black and red) were soaked in beakers filled with MMB, d-Limonene and a Mixture of MMB and d-Limonene individually. After 10 minutes of agitation at room temperature, detergency was checked.

-

Synergy in detergency with d-Limonene

Effect on plastics

MMB has a milder effect on resins than glycol ethers.

Test 1

Damage to plastics by solvents was checked.

- Test method

- Plastics were soaked in each solvent for seven days at 50oC (122°F), and the degree of swelling was measured.

| MMB | BDG | BEG | PM | DPM | |

|---|---|---|---|---|---|

| Polycarbonate | 19 | dissolved | partially dissolved | partially dissolved | dissolved |

| Polystyrene | 0 | whitening | whitening | whitening | whitening |

| PMMA | 76 | partially dissolved | partially dissolved | partially dissolved | partially dissolved |

- BDG

- Diethylene glycol mono-butyl ether

- BEG

- Ethylene glycol mono-butyl ether

- PM

- Propylene glycol mono-methyl ether

- DPM

- Dipropylene glycol mono-methyl ether

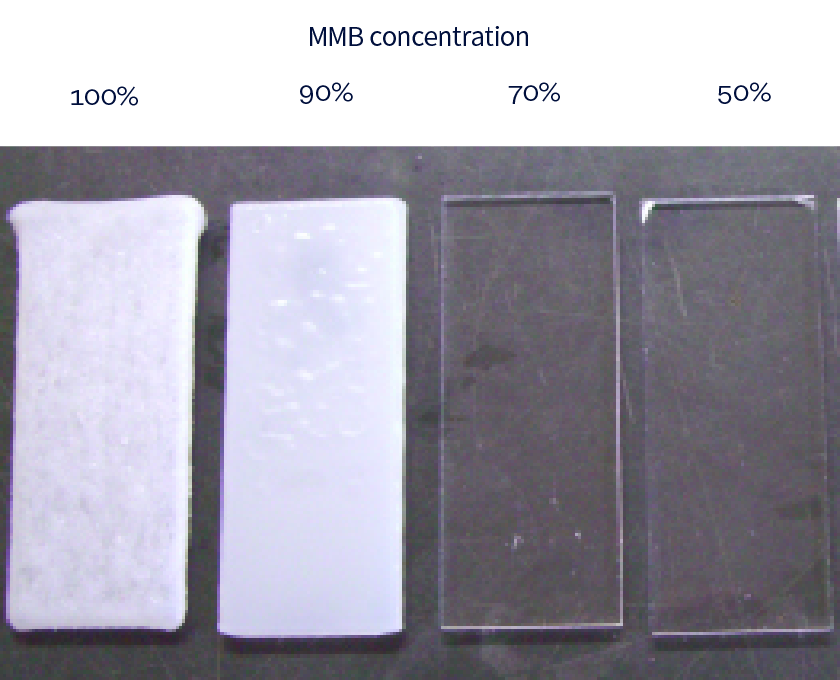

Damage to PMMA resin can be controlled by water.

Test 2

Damage to PMMA resin by a mixture of MMB and water was checked.

- Test method

-

- Mixtures of MMB and water of different ratios were prepared.

- PMMA test pieces were soaked in the mixtures for seven days at room temperature, and appearance was checked.

Improvement of stability

The MMB-based formulation is low in viscosity and high in stability at low temperatures. The viscosity and appearance of concentrated detergent formulations were checked.

- Test method

-

- Four detergent formulations were prepared with different solvents.

- The difference between them was just solvents and the other ingredients were fixed.

- Viscosity of them at room temperature and their appearance at 2oC were checked.

| Solvents | MMB | EtOH | BEG | PG |

|---|---|---|---|---|

| Viscosity (mPa・s) | 52 | 52 | 123 | 127 |

- EtOH

- Ethanol

- BEG

- Ethylene glycol mono-butyl ether

- PG

- Propylene Glycol

-

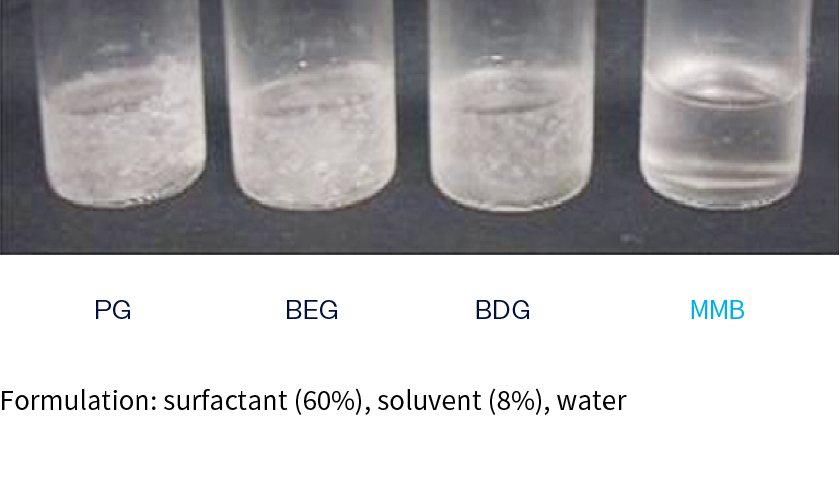

Appearance of concentrated detergent formulations (2oC)

- PG

- Propylene Glycol

- BEG

- Ethylene glycol mono-butyl ether

- BDG

- Diethylene glycol mono-butyl ether

Stability under alkaline and acidic conditions

MMB is stable at high and low pH. The stability of solvents at pH 10 and 4 were checked.

- Test method

-

- Solvents and buffer solutions were mixed.

- The mixture was stored in an oven at 50oC for 4 weeks.

- Appearance and purity were checked.

-

pH=10 (50oC, 4weeks)

-

pH=4 (50oC, 4weeks)

-

- PM

- Propylene glycol mono-methyl ether

- DPM

- Dipropylene glycol mono-methyl ether

- BEG

- Ethylene glycol mono-butyl ether

- BDG

- Diethylene glycol mono-butyl ether

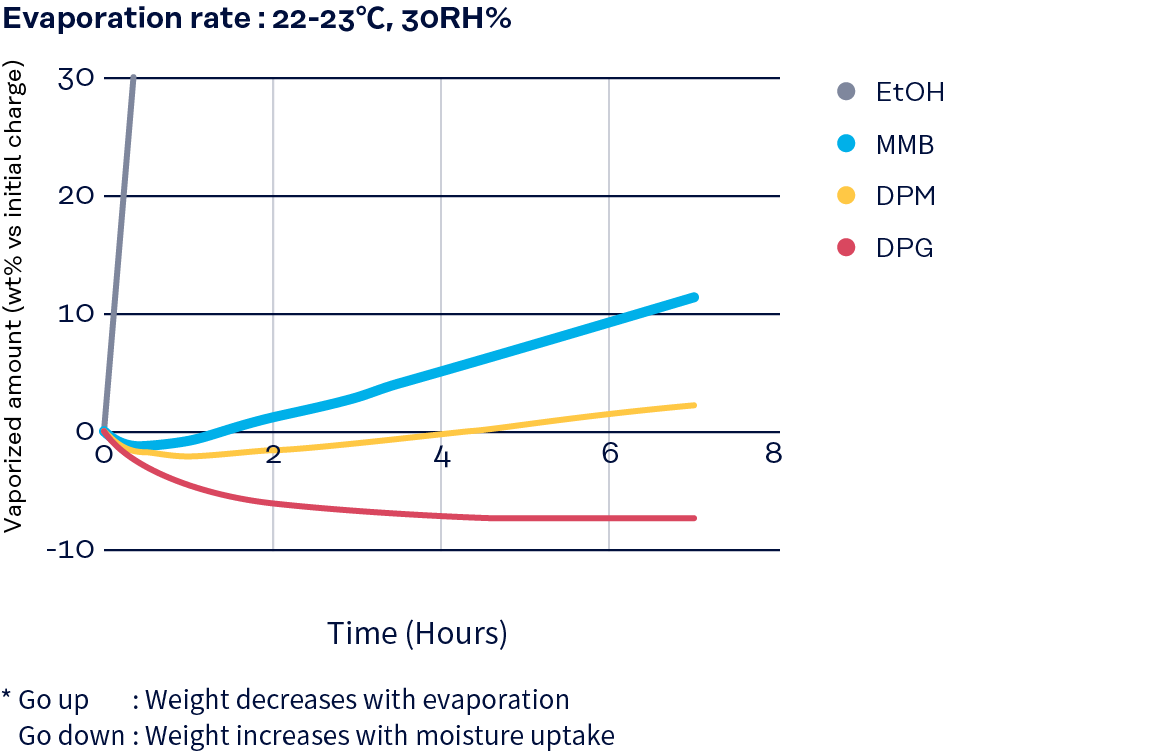

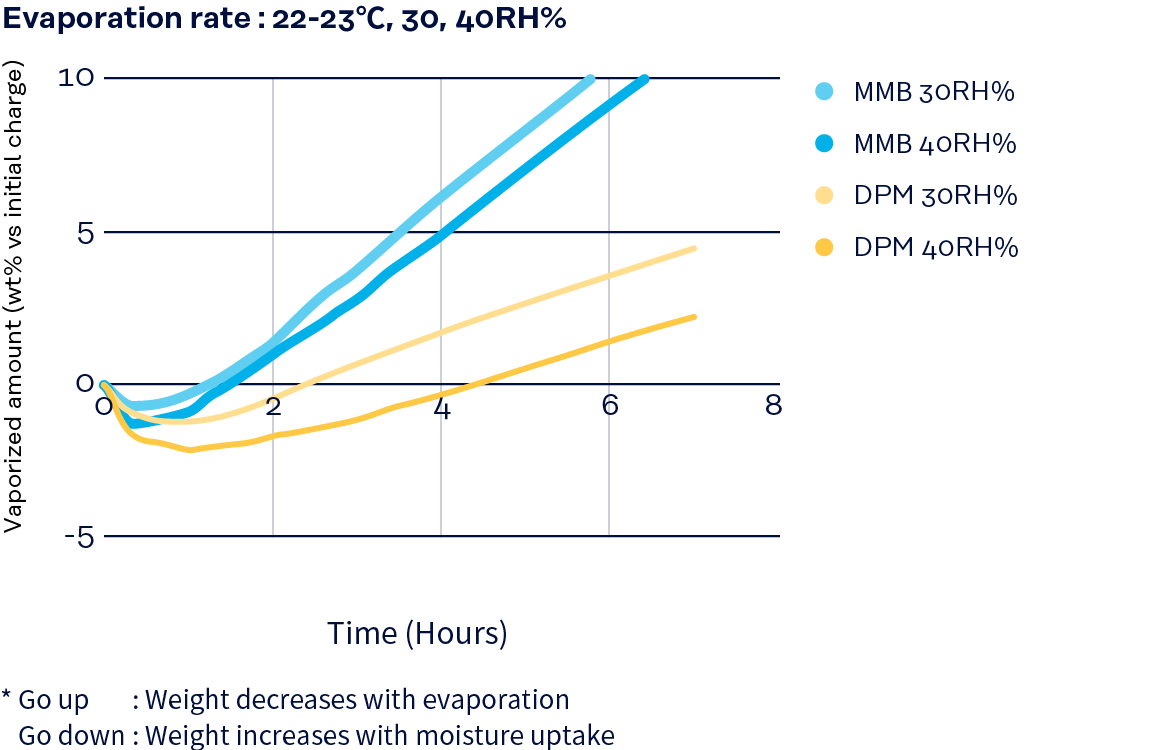

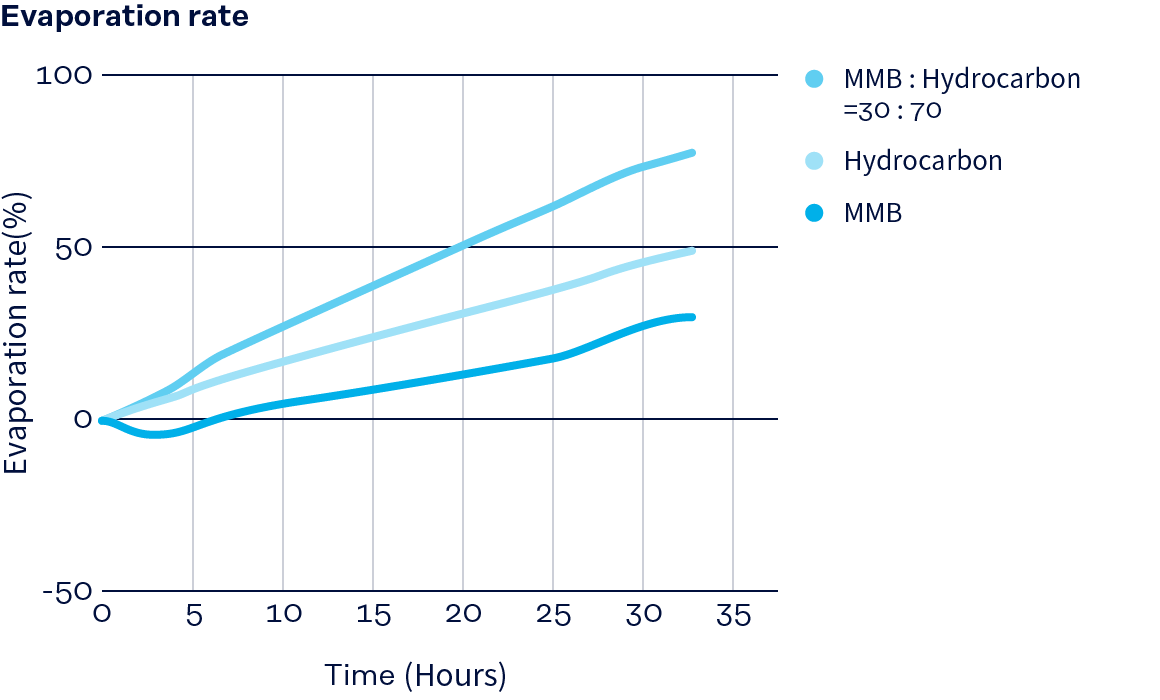

Evaporation profile

Evaporation speed can be controlled by adding MMB to water and other solvents.

- Test method

- The solvent (5.0g) was charged to a petri dish (9cm diameter). The weight of each solvent was checked at 22-23oC and 30 RH%.

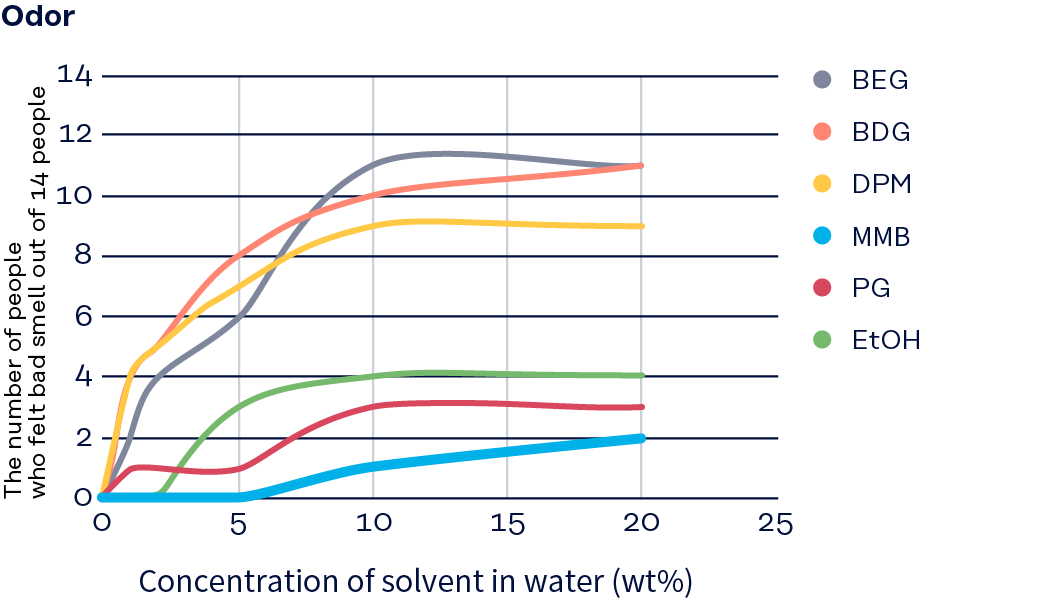

Odor

The odor of MMB is less than that of glycol ethers.

- Test method

- Each solvent was mixed with water (conc. of solvent: 0-20 weight %), and their odor was checked.

-

-

- BEG

- Ethylene glycol mono-butyl ether

- BDG

- Diethylene glycol mono-butyl ether

- DPM

- Dipropylene glycol mono-methyl ether

- PG

- Propylene glycol

- EtOH

- Ethanol

Compatibility with aroma chemicals

MMB is highly compatible with various aroma chemicals compared to glycols such as DPG.

- Test method

- The solubility of aroma chemicals in solvents was measured at 22-24oC.

| Vanillin | Ethyl vanillin |

YARA YARA |

Coumarin | Rosacetol | Musk ketone |

Tonalid | Menthol | Linalool | d-Limonene | |

|---|---|---|---|---|---|---|---|---|---|---|

| MMB | 36 | 39 | 12 | 19 | 11 | 9 | 45 | 46 | ∞ | ∞ |

| DPM | 35 | 35 | 17 | 23 | 16 | 9 | 40 | 45 | ∞ | ∞ |

| DPG | 29 | 27 | 8 | 14 | 4 | 2 | 5 | 42 | ∞ | 32 |

| PG | 36 | 15 | 2 | 8 | 1 | 1 | 1 | 42 | ∞ | 2 |

| IPG | 41 | 20 | 2 | 8 | 2 | 1 | 5 | 43 | ∞ | 10 |

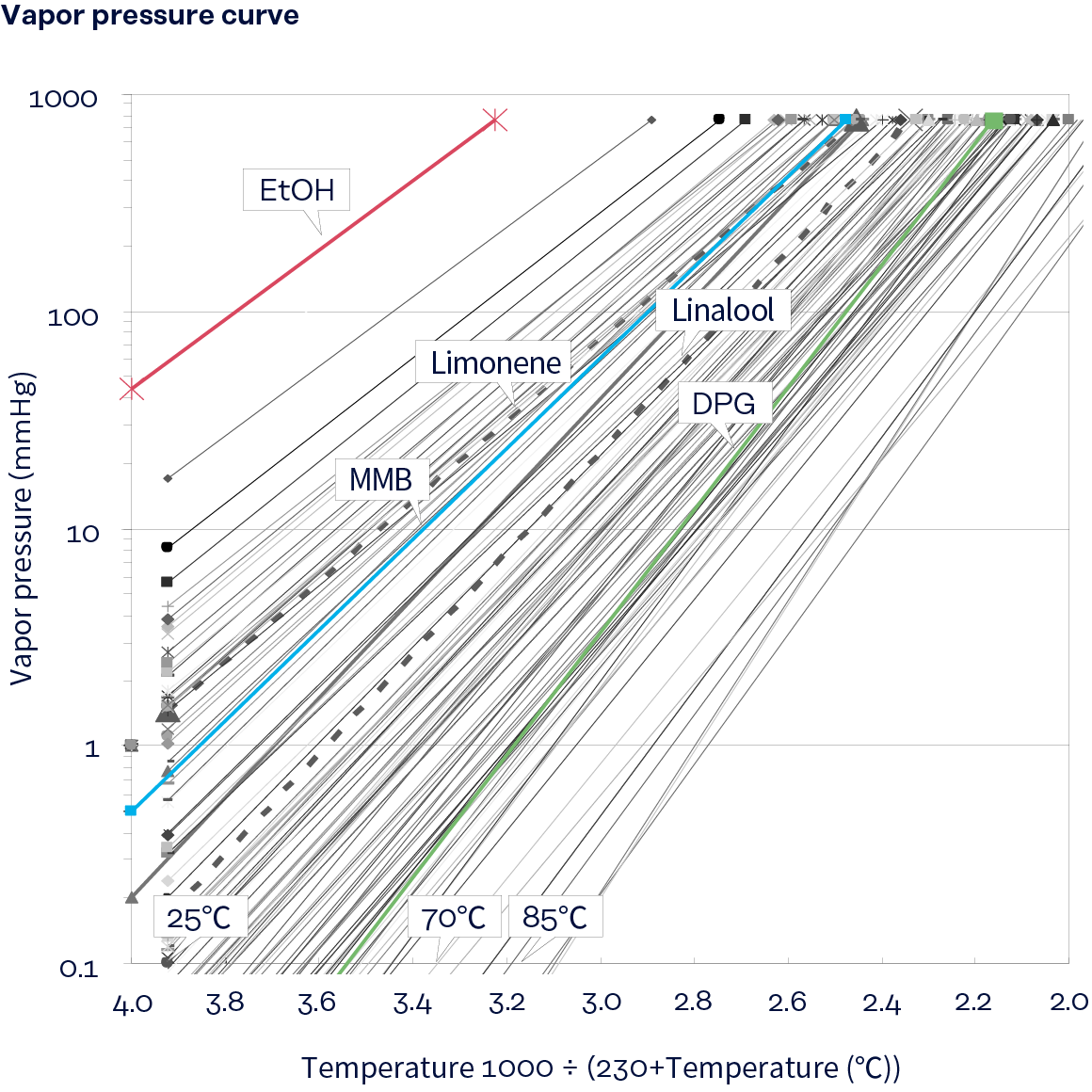

Evaporation profile - 1

MMB is located in the middle of aroma chemicals in the vapor pressure curve. And it evaporates with aroma chemicals together.

The vapor pressure of aroma chemicals and solvents was plotted.

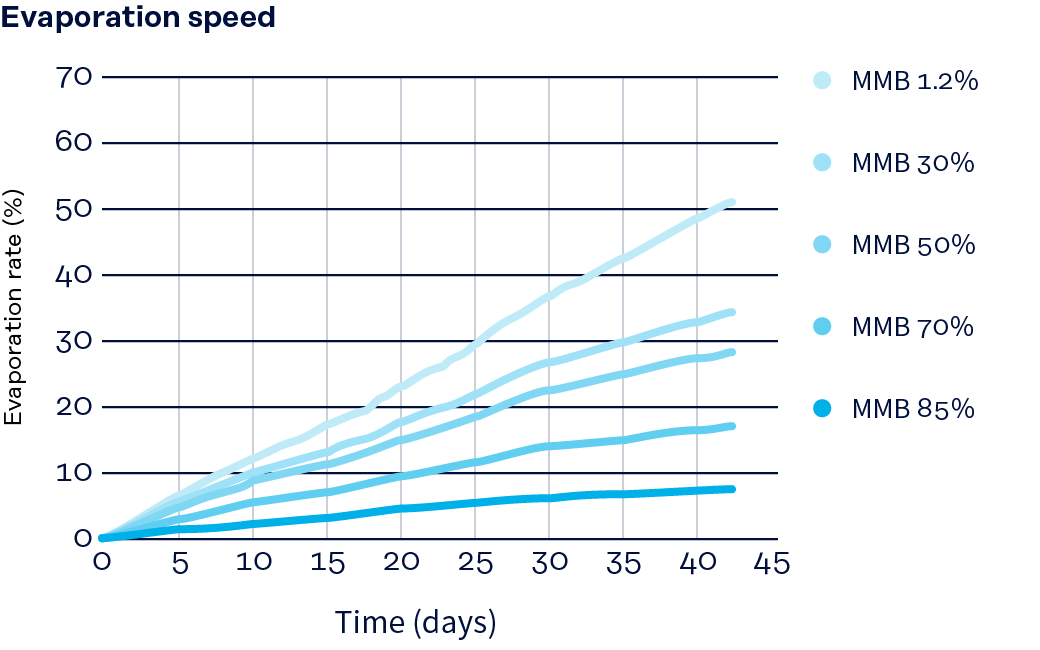

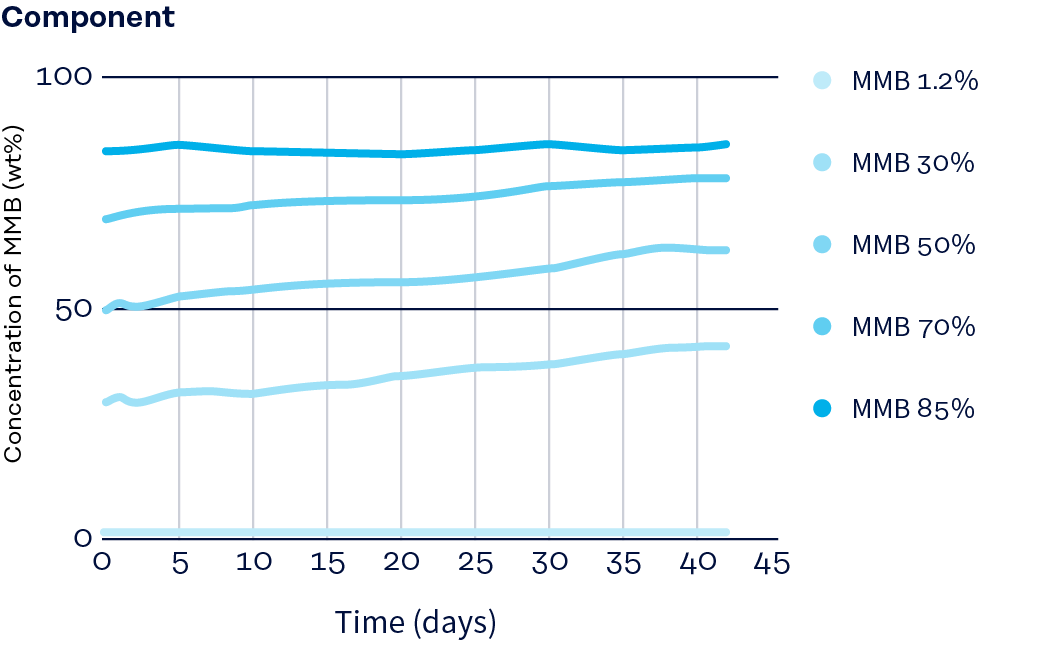

Evaporation profile - 2 water-based system

The evaporation rate can be controlled with the concentration of MMB. A long-lasting fresh scent can be achieved because of stable composition during the evaporation.

- Test method

- The evaporation profile of a mixture of MMB and water was checked. The mixture of MMB and water (200g) was charged to a beaker (300ml). They were evaporated at 25oC, and weight and components were measured.

Evaporation profile - 3 solvent-based systems

The evaporation profile of MMB is ideal. The evaporation rate of MMB system is less influenced by humidity, so the fresh scent lasts longer with MMB.

- Test method

- Solvents were charged to Petri dishes for each, and the evaporation profiles were checked. The solvent (5.0g) was charged to a petri dish (9cm diameter). The evaporation profile and weight loss were checked under 22-23oC and 30 or 40 in humidity.

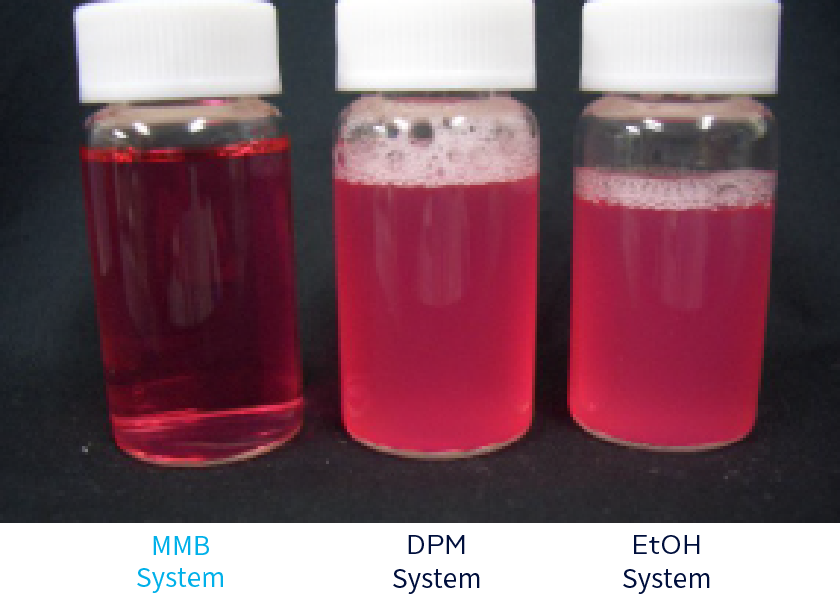

Co-surfactant effect

MMB provides a clear liquid with a smaller amount of surfactant. And MMB works as an efficient co-surfactant. MMB contributes to cost reduction of surfactant and less clogging on wick because of surfactant.

- Test method

-

- A water-based air freshener formulation was prepared (Ingredients: water, surfactant, fragrance, solvent, etc.)

- Three air freshener samples were prepared with MMB, DPM and Ethanol as a solvent (The formulation, except for solvent, was fixed).

Applications

Printing

- Ink

- Blanket cleaner

- Etch / Fountain solution

Pesticide

- Herbicide insecticide

- Wood preservative

Electronics

- Resist remover

- Cleaner for PCB

- Resist for color filter

Automotive

- Coating

- Car shampoo

- Flux

Household

- Air freshener

- All Purpose Cleaner

- Laundry detergent

Others

- Dry soap

- Fire foam

- Writing ink

Physical properties

| Flash Point (Tag's CC) | 71oC (OECD103) |

| Boiling Point | 173oC (343℉) |

| Freezing Point | <-50oC (<-58℉) |

| Viscosity | 12.5mPa・s @20oC |

| Specific Gravity | 0.91g/cm3 (20oC) |

| Surface Tension | 29.9dynes/cm @20oC |

| Evaporation Rate | 7 (n-BuAc= 100) |

| Solubility in Water | INFINITE |

| KB value | >400 |

| Solubility Parameter | 9.88 |